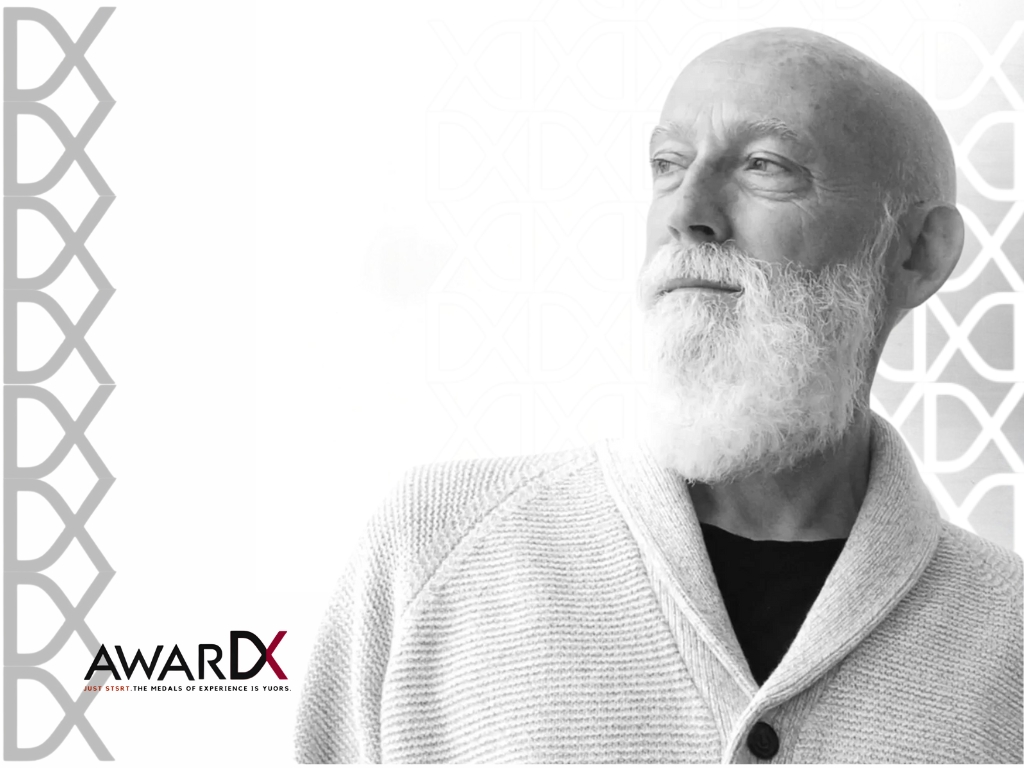

Ross Lovegrove is one of the most influential industrial designers of his generation. Trained in the UK and internationally recognized for a biomorphic, technology-forward aesthetic, Lovegrove has spent his career merging organic form with material innovation. His work sits between sculpture and product design: elegant, efficient, often technically ambitious, and always aimed at improving the human experience of everyday objects.

Design philosophy: nature, DNA and material intelligence

Lovegrove’s design language is rooted in an abiding respect for natural form and systems. He describes his method as a dialogue between technology, materials science and organic morphology — a trinity that produces work that looks grown rather than manufactured. The result is a visual vocabulary of flowing curves, minimal joins and surfaces that read as continuous rather than faceted. This philosophy makes his work attractive to brands that want products with both high visual identity and clear engineering thinking.

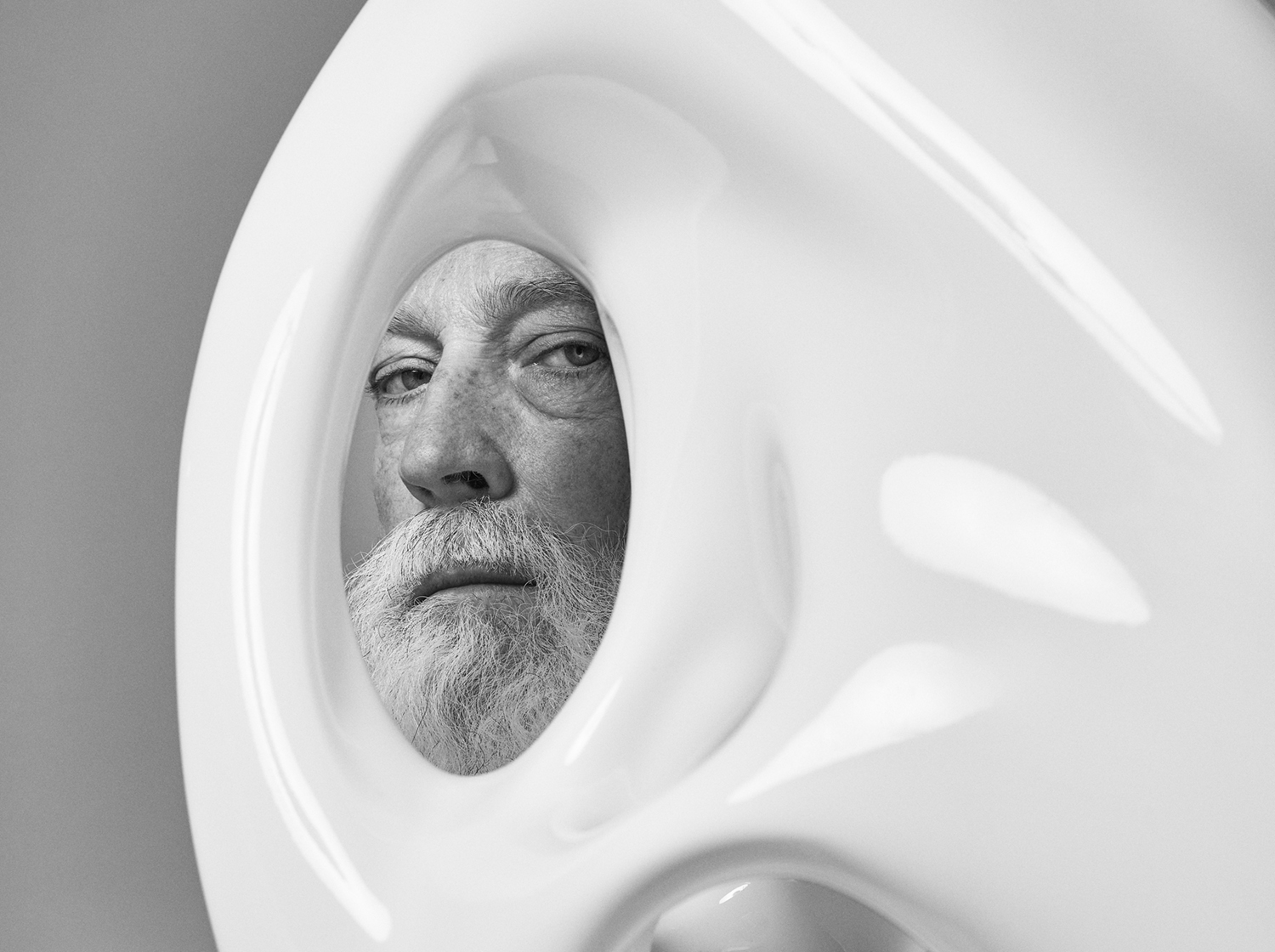

The Go Chair: concept and ambition

The Go Chair is a seminal work in Lovegrove’s portfolio and a notable milestone in contemporary furniture design. Conceived as a lightweight, sculptural seating solution, the Go Chair pursues two connected goals: to explore what new structural metals and processes make possible, and to embody an energetic, biomorphic silhouette suited to modern interiors. The design reads like a living organism — balanced, dynamic and confidently minimal.

Materials and engineering: magnesium as a structural statement

What set the Go Chair apart technically was its pioneering use of die-cast magnesium as a primary structural material. Magnesium is significantly lighter than aluminum while offering a high strength-to-weight ratio, which allowed Lovegrove to sculpt slender, flowing forms that were previously impractical at production scale. The core engineering challenge — how to realize a delicate, organic form while preserving structural integrity and manufacturability — was solved through pressure die casting, careful thickness mapping and precise finishing. The chair’s seat is offered in variants (polypropylene or veneer in different editions), making the design adaptable to indoor and outdoor contexts.

Production challenges and solutions

Turning Lovegrove’s fluid sketches into a manufacturable chair required intimate collaboration between designer, engineers and manufacturer. Die casting complex, thin sections in magnesium demanded tight tolerances and careful cooling strategies to avoid warping and defects. Surface finishing, corrosion protection and joint detailing all had to be optimised to balance longevity with the chair’s lightweight intent. The Go Chair’s manufacturing story is as important as its visual story: it’s a case study in how design ambition and production engineering must co-evolve.

Recognition and impact

Upon release the Go Chair received significant industry recognition and became a touchstone for contemporary design: it was awarded Best of NeoCon and appeared on several “best of the year” product lists. Its presence in museum and design collections reinforced its dual identity as both utility and collectible object. For brands and specifiers, the Go Chair proved that investment in material research and an unapologetically sculptural aesthetic can deliver returns in both awards and market distinction.

Why the Go Chair matters for interiors and brands

The Go Chair does more than sit in a room — it defines a spatial identity. Because of its sculptural silhouette and variety of finish options, it serves multiple roles: a signature dining chair in high-end hospitality, a statement piece in executive meeting rooms, or a collectible object in residential projects. For brands, carrying a Lovegrove design signals a commitment to innovation and premium identity; for interior designers, Go offers an element that is both functional and instantly brandable.

Sustainability, lifecycle and durability

While magnesium is energy-intensive to process relative to some materials, its excellent strength-to-weight ratio can deliver lifecycle benefits: lighter products reduce transport emissions, and durable cast components can extend product life. The Go Chair’s modularity (replaceable seat options) and robust metal frame support repair and extended service life — both important considerations for specifiers and procurement teams focused on longevity over disposability.

Collectibility and secondary market

Because of its material novelty, award pedigree and designer cachet, the Go Chair has entered collectible markets. Limited editions, museum acquisition and editorial acclaim help sustain secondary-market demand. For galleries, dealers and retailers, this creates an opportunity to position the chair not only as seating but as an investible design artifact.

Practical considerations for procurement and specification

Applications: hospitality, corporate boardrooms, high-end residential and curated retail.

Finishes: powder-coated or painted magnesium frames with polypropylene or veneered seats — choose finishes by anticipated wear and the desired aesthetic.

Installation & maintenance: metal frames require standard protective coatings and periodic inspection in coastal or high-humidity environments. Seats can be replaced or re-upholstered in many editions.

Sourcing: be explicit about finish warranties and manufacturing tolerances when ordering for large projects.

Design leadership lessons from Lovegrove’s approach

Invest in material R&D — breakthroughs often come from combining a strong concept with a willingness to test unconventional materials.

Integrate engineer and designer early — manufacturing feasibility should inform, not merely follow, design intent.

Design for identity and adaptability — a strong silhouette plus configurable finishes increases market reach.

Use awards and museum visibility strategically — recognition amplifies brand storytelling and can justify premium pricing.