Reza Raeisifar’s Keker is a modular lighting family that transforms everyday metal slats into poetic surfaces of light and shadow. The Keker project recently earned the Kioskedia award, a recognition that celebrates design intelligence, manufacturability and cultural resonance. This feature focuses tightly on Keker and the path that took it from a formal sketch to an awarded product — the designer’s intent, the development process, production choices, and why the Kioskedia jurors singled this work out. If you want one deep story to explain how a humble idea becomes an award-winning product, Keker is that story.

Product snapshot — what Keker actually is

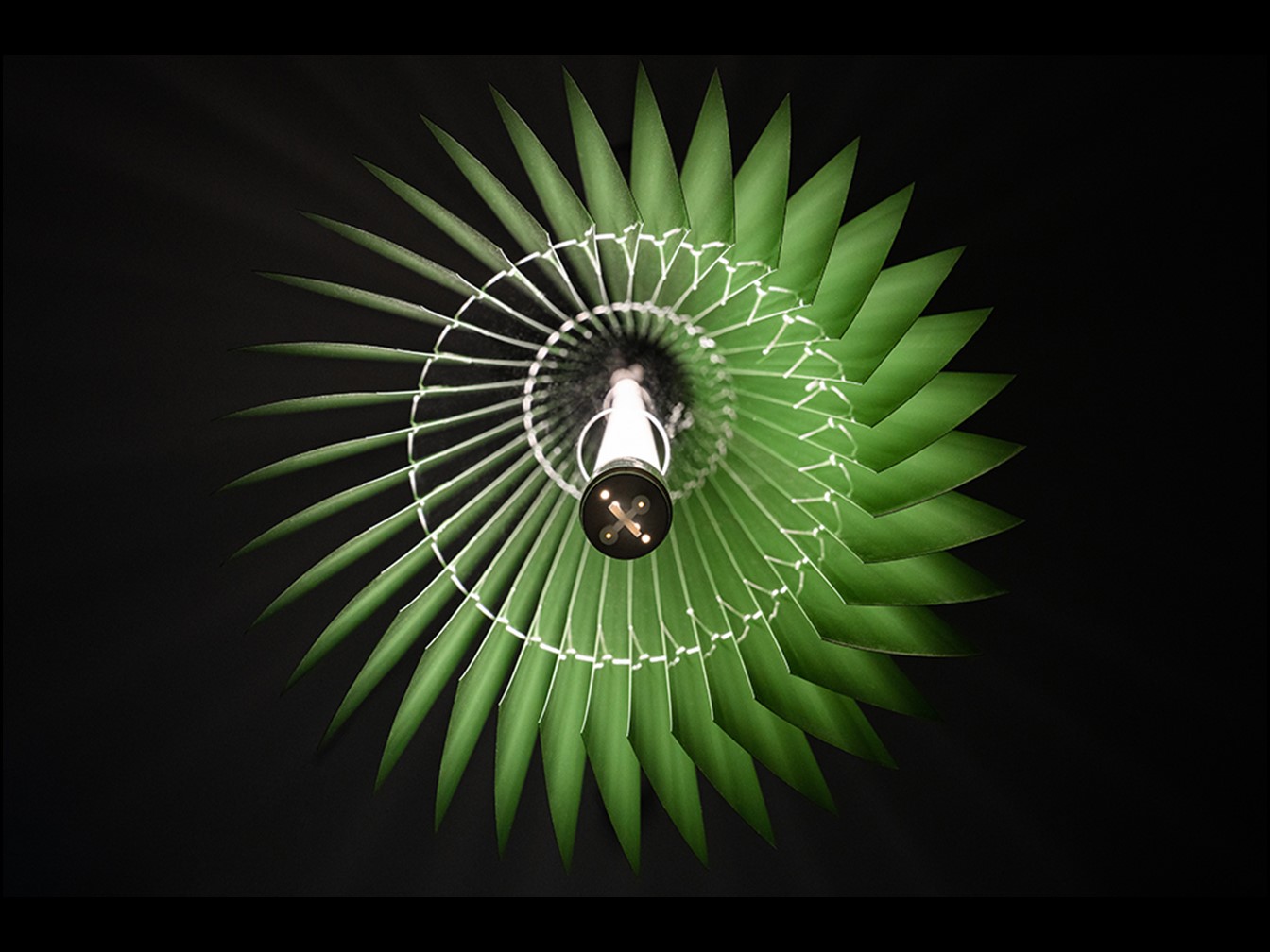

Keker is a lighting system based on a repeatable metal blade. By arranging dozens or hundreds of these blades into rings, cylinders or planar arrays, the design produces textured luminous volumes that act both as light fixtures and as spatial membranes. Variants include single pendants, clustered chandeliers and wall/ceiling panels. The system is intentionally modular: one blade unit can be combined into numerous compositions, offering specifiers and architects a flexible toolkit rather than a single aesthetic object.

Why Kioskedia recognized Keker

Kioskedia awards projects that combine practical production thinking with clear cultural or contextual storytelling. Keker’s strengths that align with that criteria are: elegant simplicity, scalable manufacturability, material honesty (often using recycled or post-industrial aluminum), and a strong experiential payoff — soft, textured lighting that reads beautifully at scale. The jury saw a project that achieves design impact without unnecessary complexity: a repeatable element yields a broad design vocabulary and real specification potential for interiors.

Designer mindset — memory, material and modular logic

Reza approached Keker with three linked intentions. First, he wanted to root the work in domestic memory — the rhythm of blinds, louvers and screens that define many interiors. Second, he wanted to honor humble materials and simple fabrication techniques, transforming them into lyrical outcomes. Third, he prioritized modularity: the repeatable blade would be the atomic unit that enables many assemblies. That mindset kept the project pragmatic while allowing expressive freedom: the blade is simple, but the systems you build from it are visually rich.

Inspiration and visual language

Keker’s visual language references architectural shading devices and textile rhythm. Up close you read the object as a set of metal blades with crisp edges; from a distance the fixture resolves into a warm, continuous glow. The alternation of light and shadow and the choice of finishes (raw metal, anodized tones, or painted surfaces) are part of the vocabulary that tunes mood, warmth and reflection. The design intentionally evokes domestic familiarity while reorienting it into a contemporary, design-forward language.

From sketch to mockup — the development path

The development of Keker followed an iterative, evidence-driven loop:

Concept sketches & rhythm studies — early work tested blade widths, spacing and curvature on paper and in simple cut-paper models to understand how silhouette and rhythm interact with light.

Low-tech mockups — cardboard and thin-sheet mockups showed how blades cast shadows and how density affects perceived warmth. These low-cost experiments prevented false assumptions that would only be visible at scale.

Material tests — small batches of metal blades were produced to study reflectivity, edge sharpness and finish behavior (oxidation, anodizing, powder coat). Recycled or salvaged metals were tested for texture and tonal variety.

Prototype lighting tests — engineers and designers tested LED placements, diffusers and thermal management to avoid hotspots or glare. They tried various internal diffusers (honeycomb, fabric, opal panels) to smooth the light while preserving the external texture.

Full-scale mock-ups and installation trials — a full-size pendant and a wall panel were installed temporarily to assess spatial effect, hanging geometry, and maintenance access. These trials refined suspension details and driver placement.

This staged approach let Reza refine both the poetry of the light and the pragmatic requirements of manufacture and installation.

Engineering and mechanics — small details, big outcomes

The brilliance of Keker is in how small mechanical and engineering choices produce an elegant result. Important technical notes included:

Indexed spacers to guarantee consistent blade spacing across arrays and to simplify on-site assembly.

Concealed fasteners and clip-in systems that allow blades to be replaced without disassembling the entire fixture.

Internal diffuser strategies that separate the light-engine from the visible metal texture so the blades create shadow while the diffuser ensures even illumination.

Thermal planning using remote drivers or ventilated housings to keep LEDs cool in dense arrays.

These seemingly minor decisions preserved the visual continuity that makes Keker read as a material surface rather than a cluster of parts.

Materials and finishes — choosing tone and tactility

Material selection shaped Keker’s identity. Options typically include recycled aluminum (for its light weight and honest texture), anodized finishes (to create muted metallic tones), and painted versions for consistent colorways. Surface finish matters because the blades simultaneously reflect and absorb light; subtle variations change warmth and visual depth. Reza made choices that balance manufacturability, cost and the aesthetic objective: to appear crafted, tactile and slightly industrial rather than factory-perfect glossy.

Manufacturing strategy — small-batch to scalable runs

Keker’s geometry is optimized for efficient production. Blades can be stamped or laser-cut and then bent or finished with minimal secondary processing. This means small-batch artisan runs are possible while larger orders can scale with press or CNC setups. The modular assembly reduces per-unit complexity: panels are composed of identical blades and indexed rings, which simplifies inventory and onsite assembly. The manufacturing plan intentionally lowers barriers for producers, which is one reason the product appealed to Kioskedia — it has clear routes to commercialization.

Sustainability and lifecycle thinking

Keker’s environmental strategy has several elements: using recycled metal where possible, designing for repair (replaceable blades), and choosing long-life LED sources. Modularity supports repairability — if a blade is damaged, only that element is replaced — and the use of common driver types reduces electronic waste. Moreover, the lighting’s efficiency and long-lasting LEDs reduce operational energy use in commercial installations, which is an important sustainability metric for specifiers.

Installation and maintenance — practical considerations

Keker arrays require thoughtful installation planning: accessible driver locations, safe suspension points, and clear wiring channels. The design’s modularity simplifies shipping and on-site assembly: panels can be hoisted and connected sequentially. Maintenance is straightforward because blades clip in; cleaning is done with a soft cloth and mild cleaner, and remote drivers minimize ceiling service interventions. These practicalities make Keker attractive to hospitality and commercial clients who value low-life-cycle costs.

How the Kioskedia jury saw Keker — clarity, craft, and feasibility

Kioskedia juries value projects that are conceptually strong and commercially credible. Keker hits both notes. The jury emphasized the project’s ability to convert a simple repeatable unit into an expansive design language, and they noted the clear manufacturing pathway. In short, they saw a design that solves a real brief (beautiful, specifiable lighting) with an elegant, scalable system rather than a one-off object — the kind of work Kioskedia aims to spotlight.

Market fit — where Keker truly shines

Keker is especially compelling for:

Boutique hotels and hospitality lobbies where a textured light installation becomes a brand-defining element.

Restaurants and bars seeking a memorable night-time silhouette and tactile interior identity.

Retail environments where modular arrays can be adapted for display lighting and ambiance.

Residential projects that want a sculptural centerpiece with a subtle industrial tone.

The modular approach allows specifiers to order bespoke sizes while relying on a known system and predictable lead times.

Presentation and storytelling — selling the idea to buyers

To sell Keker effectively, package three narratives: the material story (recycled metal, tactility), the system story (modularity, repairability), and the experiential story (how light and shadow shape a space). Visual assets should include hero shots at dusk, detailed close-ups of blade edge and finish, and short video loops that show the fixture’s night silhouette and in-context scale. For commercial proposals, include a simple configuration guide so architects can quickly specify blade counts, diameters and diffuser options.

What the Kioskedia award changes for the project

Winning Kioskedia accelerates adoption in multiple ways: it provides a credible third-party endorsement for specifiers, it simplifies trade press placement, and it opens dialog with manufacturers and distributors who scan awards for commercially viable designs. For a project like Keker, the award lowers the friction to acceptance by showing that the work has passed expert scrutiny on innovation, execution and feasibility.

Designer lessons — how Keker teaches product teams

Design a unit, not just a product. A repeatable atomic element expands possibilities far beyond a single SKU.

Prototype at human scale early. Lighting behaves differently when scaled; full-size mockups reveal surprises.

Engineer for serviceability. Modular, replaceable components lengthen product life and lower TCO for buyers.

Keep manufacturing practical. Elegant shapes should be achievable with predictable processes; this helps adoption.

Tell a layered story. Material honesty + system logic + lived experience create commercial resonance.

Curatorial and editorial opportunities

Keker’s visual richness and system logic make it ideal for exhibitions, trade fairs and editorial features. A curated show could include a series of Keker panels at different densities to demonstrate mood shifts; editorial spreads should juxtapose material close-ups with ambient room shots to show both craft and atmosphere.

Final takeaway — simple idea, broad impact

Keker shows how a restrained, well-executed idea — a blade and its rhythm — can yield a powerful design language. The Kioskedia award is recognition that the project is not just visually compelling but also thoughtfully engineered and commercially credible. For designers and brands, Keker is a reminder that scalability, repairability and emotional resonance are the three ingredients that turn a good object into an awarded system.

Official links for further reading:

https://award.kioskedia.com/en/winner/1392