Carter McGuyer is an industrial designer known for solving everyday problems with clean, user-focused solutions. His work spans consumer products, housewares and tools where ergonomics, material honesty and manufacturing pragmatism meet strong visual identity. The Microplane Elite Series Grater is one of the best examples of his practice: a humble kitchen tool rethought so that performance, comfort and shelf-appeal all come together.

Product at a glance — what the Elite Series is

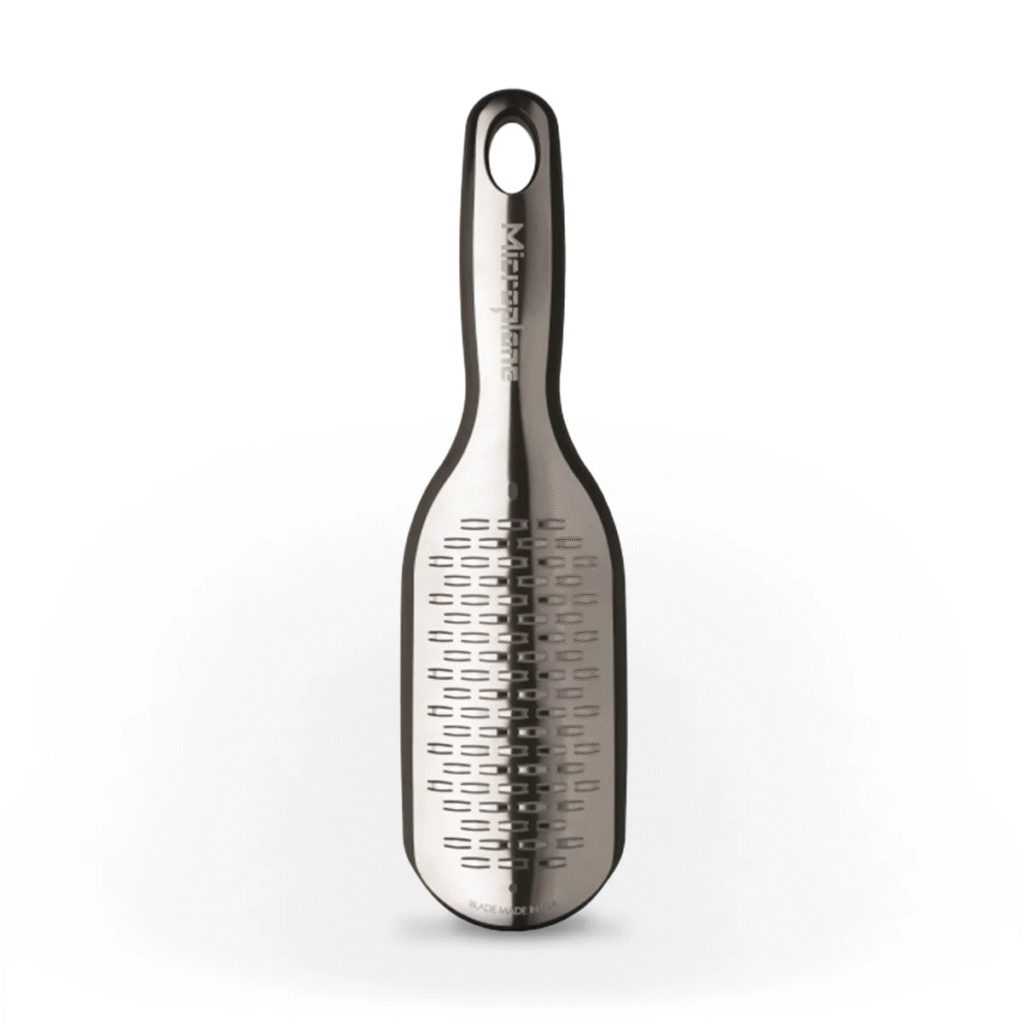

The Microplane Elite Series Grater is a refined hand grater family designed for zesting, grating and fine shredding. Compared with earlier graters, the Elite introduces refinements in handle ergonomics, blade mounting, body geometry and materials to make grating faster, safer and less fatiguing. It reads like a professional tool but is made for everyday kitchens: efficient teeth geometry for clean grating, comfortable non-slip grips, and durable surfaces that stay sharp and are easy to clean.

Why the product matters — performance meets recognition

What makes the Elite Series noteworthy is not a single flashy feature but the ensemble of improvements that designers and cooks notice in use. It raises a basic kitchen task — zesting a lemon, grating parmesan, or shredding nutmeg — into a precise, repeatable gesture. The product has received industry recognition and awards, which reflects both its engineering quality and consumer impact. For a blog, it’s a great subject because you can tell a complete story: brief (problem), research (how cooks work), design (how those problems were solved), and outcome (a usable, award-winning product).

Designer mindset — empathy, reduction, and craft

McGuyer’s framing for the Elite Series is straightforward: start with observation. He watches how people hold graters, where fingers slip, how food clogs teeth, and how awkward angles cause fatigue or accidental cuts. From that user empathy he applies three guiding rules: reduce unnecessary complexity, amplify the affordances that help safe use, and specify materials and tolerances that maintain performance over time. The goal is democratic — make a professional feel that belongs in every home.

Research & brief — grounding the problem

The project begins by mapping use cases and pain points: what tasks do people actually perform with a hand grater; what are common failure modes (slipping, clogged holes, bent blades, accidental nicks); and what trade-offs exist between sharpness, safety and cleanability. Competitive teardown studies (examining other graters), interviews with cook-shop staff and short in-kitchen observations produce a tight brief that balances performance targets (grating speed, particle size consistency) with production constraints (cost, manufacturability, durability).

Ideation and concept generation

Early ideation explores handle shapes, body geometry and blade profiles. McGuyer and team sketch dozens of variants, make quick foam or 3D-printed handles to test grip, and prototype different blade mounting arrangements to assess rigidity and cleaning access. Several directions are narrowed to a few concept models that satisfy ergonomic tests: handle diameter and contour, angle between blade and handle, and finger guards or stops that reduce slippage.

Material choices and engineering decisions

Key technical choices determine the Elite’s success: blade steel grade, heat-treatment for long edge life, surface finish to resist clogging, and handle material for comfortable, non-slip grip. The team balances premium stainless steel for the blade with injection-moulded or over-moulded elastomer handles. Blade mounting must be secure (no wobble under load) yet manufacturable: common solutions use riveted or clipped retention systems that allow consistent gap control and easy cleaning.

Prototyping and user testing

Prototyping is iterative and hands-on. Early prototypes test sharpness and edge spacing on real food (citrus peel, hard cheeses, root spices). Designers measure grating efficiency (how fast, how clean), ergonomics (subjective comfort and muscle fatigue after repeated use), and safety (how often skin contact occurs). Tests reveal small but impactful refinements: slight bevel changes to reduce clogging, a revised handle taper for different hand sizes, and minor adjustments to the blade angle to keep the grater close to the work surface while preserving clearance for food.

Manufacturing readiness — keeping design buildable

Carter designs with manufacturing constraints in mind. Blade production involves stamping and heat treating; controlling tolerances is critical so the teeth remain aligned and sharp. Over-moulded handles require careful gate placement and material selection to avoid seam discomfort. The design package includes manufacturing drawings, assembly fixtures, and QC checks (blade straightness, rivet torque, handle adhesion). By integrating manufacturing early, the Elite hits quality targets at retail price points.

Finish, maintenance and longevity

A grater that dulls quickly or traps food will disappoint. The Elite Series specifies finishes and tolerances that resist corrosion and food adhesion. Surface finishes are chosen to reduce residue build-up, and the geometry of teeth minimizes clogging. The handle materials are selected for cleaning durability and to avoid absorbing odors or staining. Clear maintenance guidance (hand wash vs dishwasher, storage tips) and replaceable parts (if applicable) extend the product’s usable life — a design value both for users and for brand reputation.

Awards and industry recognition

The Elite Series has received industry accolades for design and function. Awards validate that the product meets both consumer needs and professional criteria: performance, manufacturability and aesthetic quality. For a blog, awards are useful narrative beats — they signal third-party verification and create opportunities to quote juror commentary or show badges on product pages.

Commercial impact and brand fit

For Microplane, the Elite Series strengthens market position by offering a premium, evidence-driven tool that appeals to both home cooks and professionals. It supports retail strategies (specialty kitchen stores, premium department stores, online marketplaces) and becomes easier to promote through demos, cook shows and influencer reviews because its improvements are tangible in use tests. For Carter McGuyer, the work exemplifies how focused, human-centred design can bolster a brand’s core product line.

How to present the product in editorial or retail channels

To show the Elite Series effectively: lead with hero imagery of the tool in action (zesting citrus over a bowl, grating hard cheese), include close-ups of teeth geometry and handle detail, and add a brief “how we tested it” section describing real-world user trials. Short video clips of the grater being used (slow motion of zest falling, cross-section of particle sizes) communicate performance faster than text. Technical specs (materials, dimensions, care) and endorsement quotes (chefs or awards) complete a convincing product page.

Design lessons for teams and students

Start in use, not in visuals. Observe real users to find friction points worth solving.

Prototype with the real material. Food behaves differently than foam; test with actual ingredients early.

Engineer for repeatability. Small tolerances in blades matter for performance and QC.

Design the whole experience. Grip, cleaning, storage and longevity are as important as immediate performance.

Use awards as part of a larger narrative. They help, but sustained product success comes from consistent quality.