Michael DiTullo (often styled Michael DiTullo / D2Lo) is an award-winning industrial and footwear designer whose career spans high-profile collaborations with global sports and lifestyle brands. He has worked across footwear categories for major names — including projects associated with the Jordan brand — blending athlete collaboration, brand thinking and hands-on footwear engineering to deliver commercially successful and culturally resonant sneakers.

Product focus — the “Jordan” project at a glance

When we say “Jordan” in DiTullo’s portfolio we mean his direct involvement in footwear briefs for the Jordan/Nike universe (including concept and production work for athlete-led projects such as the Hangtime and other athlete collaborations). These pieces combine performance needs (fit, cushioning, traction) with strong brand identity and storytelling — the hallmark of designer-led sneakers that both perform on court and travel into everyday culture.

Why this shoe matters — bridging sport, identity and product design

A great Jordan shoe is never only about specs; it’s about identity. DiTullo’s work on Jordan projects demonstrates how a sneaker becomes a cultural object: athlete input is translated into functional features (locking fit, impact protection) while the visual language — silhouette, materials, color blocking — communicates story, status and brand legacy. That combination is what lets a shoe perform athletically and register as a design icon off court.

Designer mindset — athlete empathy, brand clarity, and iterative craft

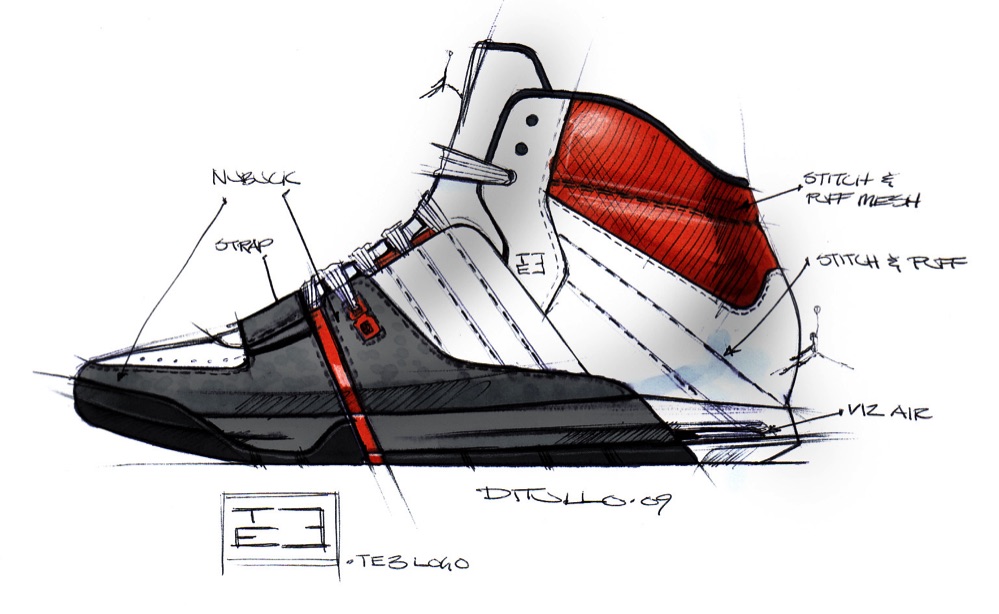

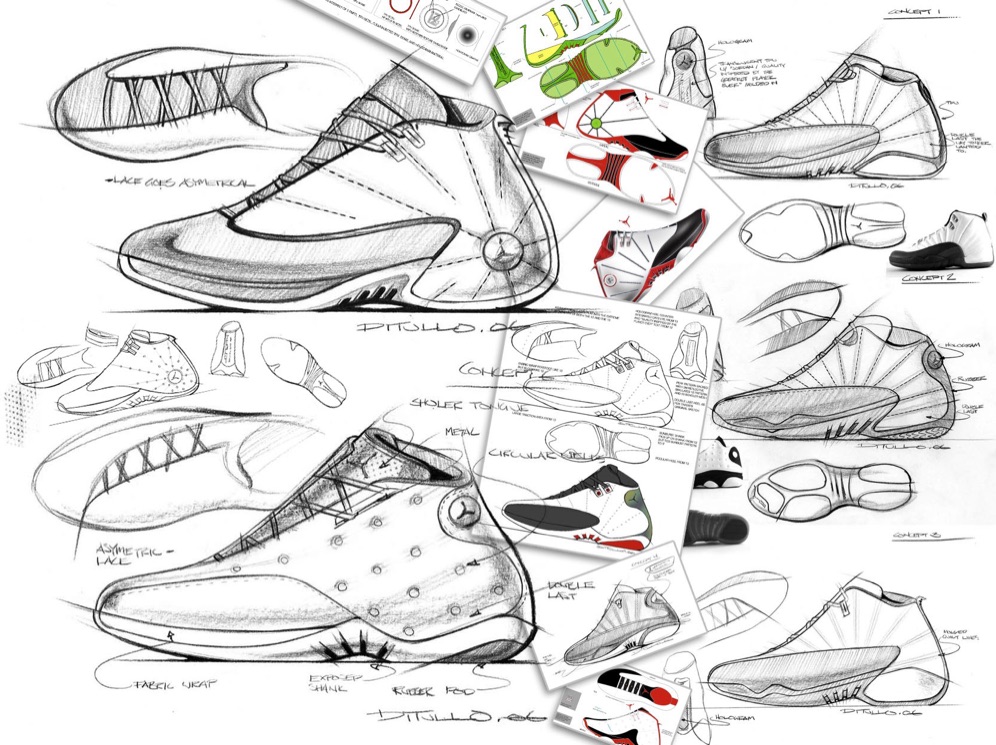

DiTullo approaches footwear design from three converging mindsets: empathy for the athlete (observing movement and needs), respect for brand DNA (what Jordan stands for in sport and culture) and practical, iterative craft (rapid sketches, last and sole development, and repeated prototyping). He often frames design problems around human rituals — how a player ties shoes, how the foot expands under load — and uses those observations to guide both engineering choices and visual decisions.

From brief to finished shoe — a typical development process

Brief & user research: start with athlete interviews and performance targets (court traction, cushioning response, ankle support).

Concept sketching & storytelling: quick ideation sketches explore silhouettes, materials and identity cues that reference the Jordan legacy while proposing something fresh.

Last & fit iteration: create lasts (3D foot forms), fit prototypes and adjust volumes to balance lockdown with comfort.

Midsole & outsole engineering: select cushioning technology, tune foam durometers and design traction patterns that meet testing metrics.

Mockups and wear-testing: field tests with athletes (and lab tests for durability, flex, and traction), then multiple rounds of refinement.

Material selection & manufacturing prep: finalize upper constructions, stitch maps and bill-of-materials; prepare tooling, molds and production run tolerances.

Launch & cultural roll-out: coordinate product storytelling, athlete endorsements and retail placement so the shoe lands as both a performance product and a cultural moment.

This loop—observe → prototype → test → refine—ensures the shoe meets both technical targets and the emotional expectations of the Jordan audience.

Material and engineering highlights typical of DiTullo’s Jordan work

DiTullo’s projects balance lightweight uppers (engineered knits or layered meshes) with structured overlays for lockdown, responsive midsoles tuned to player feedback, and outsole patterns engineered for specific court surfaces. Small details — asymmetric lacing, heel geometry, internal gussets — are treated as both performance enhancers and branding opportunities. The result is footwear that reads as intentional at every scale: from the stitches to the silhouette.

Prototyping & athlete testing — the non-negotiable phase

No Jordan shoe is production-ready until athletes accept its feel. DiTullo emphasizes rapid prototyping (3D printed molds, quick-turn uppers, iterative lasts) and short feedback loops with players and performance labs. Objective metrics (force plate data, abrasion cycles) are combined with subjective athlete feedback to arrive at the final set of compromises that deliver both performance and personality.

Manufacturing & scale considerations

Transitioning from prototype to production demands early conversations with manufacturing partners: specifying material suppliers, ensuring mold tolerances, and validating assembly sequences that preserve the design’s visual integrity at scale. DiTullo’s experience working with global brands helps anticipate common pitfalls—variation in stitch density, glue application inconsistencies, or outsole compound shifts—and he embeds quality checkpoints into pilot runs to avoid surprises.

Brand impact and cultural reception

Designers like DiTullo understand that a Jordan project amplifies brand narrative. Successful releases earn placement in editorial features, collector interest, and often secondary-market attention. The design must therefore be legible at multiple levels: technical credibility for players, visual desirability for fans, and narrative depth for press and collaborators.

How to present the shoe in editorial and product pages

Lead with a dynamic hero image showing the shoe in motion or in context (court or lifestyle).

Include a “making” strip: sketch → prototype → athlete testing → factory shot.

Supply a concise tech table (materials, weight, midsole tech, outsole pattern).

Add a short designer note (1–2 paragraphs) describing the design intent and athlete input.

This combination helps both athletes and buyers quickly grasp why the shoe matters.

Lessons for designers and product teams

Start with the user in motion. Athletic design must be rooted in real movement data.

Prototype fast, test faster. Short loops reduce costly late changes.

Treat aesthetics as functional language. Visual choices should signal performance as well as identity.

Plan manufacturing early. Tooling and assembly strategies determine which design moves survive scale.

Coordinate launch storytelling. Athlete voice, press assets and retail timing convert a good shoe into a cultural event.